Pavers are manufactured to be durable

Pavers are a popular choice for driveways, sidewalks, patios and more because of their ability to withstand wear and tear

Pavers are manufactured to be durable

Pavers are a popular choice for driveways, sidewalks, patios and more because of their ability to withstand wear and tear. They are manufactured with high-strength materials that make them strong enough to resist extreme weather conditions and foot traffic. In addition, they offer a wide variety of shapes, sizes, colors and textures that can be used to create a custom look in any outdoor space. This blog post will explore the manufacturing process behind pavers and how this contributes to their durability. Read on to learn more!

What are Pavers?

Pavers are manufactured to be durable and will last for many years with proper care. They are an excellent choice for high traffic areas such as driveways, patios, and walkways. Pavers come in a variety of colors, sizes, and textures to suit any home’s needs.

Types of Pavers

There are numerous types of pavers available on the market. The most common type of paver is the concrete paver. Concrete pavers are made from a mixture of Portland cement, sand, water, and other aggregates. They are available in a variety of colors and can be custom made to suit your specific needs.

Another type of paver is the brick paver. Brick pavers are made from fired clay and come in a variety of colors and sizes. They are typically used for driveways, walkways, and patios.

Stone pavers are another popular option. They are available in a variety of materials including granite, limestone, slate, and bluestone. Stone pavers are durable and elegant, making them a popular choice for outdoor spaces.

Finally, rubber pavers are a newer option that is becoming increasingly popular. Rubber pavers are made from recycled tires and provide excellent traction in wet or icy conditions. They are also slip-resistant and easy to clean, making them ideal for pool decks and other high-traffic areas.

The Manufacturing Process

Pavers are manufactured to be durable. The manufacturing process for pavers includes the selection of raw materials, the preparation of the raw materials, the molding of the pavers, and the firing of the pavers.

The first step in manufacturing pavers is the selection of raw materials. The type of raw material used will determine the type of paver that is produced. For example, clay pavers are made from a naturally occurring clay deposits, while concrete pavers are made from a mixture of cement, sand, and aggregate. Once the raw materials have been selected, they must be prepared for use in the manufacturing process.

The next step in manufacturing pavers is the molding of the pavers. Pavers can be molded by hand or by machine. Hand molding is typically used for small batches of pavers, while machine molding is used for larger batches. After the pavers have been molded, they must be fired in order to harden them. Firing can be done in a kiln or in an oven.

After the firing process is complete, the pavers are then ready to be installed.

What Materials Are Used to Make Pavers?

Materials used to make pavers include concrete, stone, brick, and asphalt. Pavers are made from a variety of materials, each with its own benefits and drawbacks.

Concrete is a popular choice for pavers because it is inexpensive and easy to work with. However, concrete can be susceptible to cracking and chipping. Stone is a more durable option, but it is also more expensive. Brick is another durable option, but it can be difficult to install. Asphalt is a less popular choice for pavers because it is not as durable as other options, but it is less expensive.

Why Choose Pavers?

Pavers are built to last—they’re strong and resilient against wear and tear. With proper installation, they can resist cracking and heaving due to temperature changes or ground movement. They also don’t chip or break easily like concrete can, so you won’t have to worry about regular repairs. In addition, pavers are easy to replace if one of them is damaged. Plus, they come in a variety of styles, colors and textures to fit any landscape design. worry about replacing them as often.

The Benefits of Pavers

Pavers are made to withstand high traffic areas and last for many years. They don’t require annual maintenance like other types of pavement, so you can save time and money in the long run. In addition, pavers can add value to your home or business.

Different Ways to Use Pavers

There are many ways to use pavers. Some popular uses include:

- Patios: Pavers can be used to create an attractive and durable patio. They are available in various sizes and colors.

- Walkways: Pavers can be used to create pathways in gardens or other outdoor spaces. They provide a decorative way to move around your property.

- Retaining walls: Pavers can also be used to construct retaining walls, which help keep dirt from shifting or eroding away.

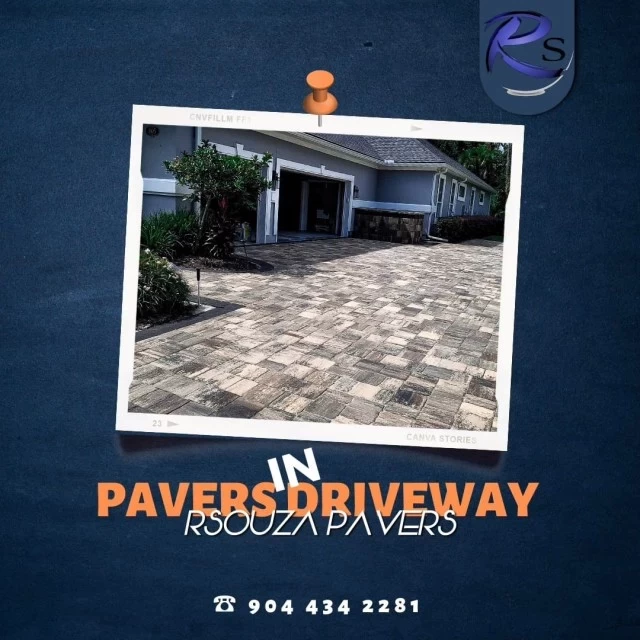

- Driveways: For a long-lasting driveway, pavers offer a great solution. They come in a range of styles and colors that can add visual appeal to your home’s exterior design.

- Outdoor kitchens and bars: If you want an outdoor kitchen or bar area, consider using pavers as an easy DIY project. You’ll get quality results that are sure to last for years to come.

- Fire pits: Another great use of pavers is building fire pits for outdoor entertaining areas. This is an easy and affordable way to add warmth and ambiance to any patio or backyard space.

- Walkways

- Driveways

- Pool decks

- Outdoor kitchens

- Fire pits

Maintenance Tips for Making Your Pavers Last Longer

It is important to regularly clean your pavers to prevent dirt and debris from building up and causing stains or other damage. You can use a garden hose or pressure washer to remove any dirt or debris that has accumulated on the surface of your pavers.

In addition to regular cleaning, you should also seal your pavers on a yearly basis. Sealing helps to protect the pavers from weather damage and prevents staining. You can find sealing products at most home improvement stores.

If one of your pavers becomes damaged, you can usually replace just the individual paver without having to replace the entire patio or walkway. Pavers are designed to be durable, but they can still be damaged by heavy traffic or severe weather conditions. If a paver is cracked or chipped, you can use a hammer and chisel to remove the damaged paver and then install a new one in its place.

Conclusion

In conclusion, pavers are a great option for outdoor surfaces because they are manufactured to be durable and can stand up to different climates and weather conditions. They come in a range of styles and textures, so you're sure to find something that matches the look of your home and complements its existing aesthetics. Pavers also require minimal maintenance, making them an ideal choice for busy homeowners who don't have time for constant upkeep. With all these benefits, it's no wonder why pavers remain one of the most popular materials used in landscape design today!

Pavers, Durable, Manufacture, Long-lasting, Hard-wearing, Enduring, Resilient, Solid, Robust, Sturdy